solidus Carbide Rods

![]() Introductio solida Carbide Rods

Introductio solida Carbide Rods

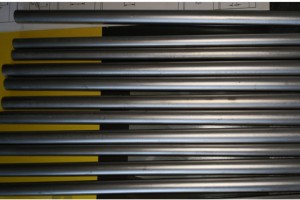

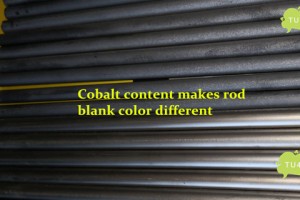

Virga carbida solida maxime facta est ex carbide tungsten, cobalte metallo ligante et quibusdam aliis medicamentis functionis additis ut formula postulat, per mixtionem materiae, extrudendo, prae-sinter, figura modificationis processus producentis tunc in pressione depresso sinteratus. Cum characteribus altae duritiae, altae fortitudinis, stabilis chemicae, humilis dilatationis coefficientis, electricae et caloris operandi, virgae carbidi sinteretae late applicantur in area fabricandi industriae, exempli gratia, ut microform exercitio in PCB industria, vectura electrode in communitate optica. industria, exercitio, stirps terebra, tip, pusher, gerunt renitentes partes praecisiones, CNC reamer et laminae cum coolant foramen in machinando industria.

Sicut vectum carbidum, Toonney tungsten officinas plantae metallicae magnas officinis officinis officinis inclusas solidas virgas, virgas cum foramine refrigescente cochlearum recti / virgas formatas secundum exigentiam emptoris et T formatam etc.

Carbide virgae solidae, nulla meatum intus coolant. Formam materiam 10 graduum frequentissimam habemus, exempli gratia, virgas pro terebra PCB, micro molaribus milling, carbide ferrum vidi, terebras ad machinationem aluminii mixturae, basin stannum aeris, admisceri basi chalybis et; Wolfram carbide etc. Qualitatem in unoquoque necessario gradu stricte moderamur, possumus dicere bonam qualitatem esse unum emolumentis quo in hac industria nos stare facit.

Wolfram carbide: Wolfram carbide compositum est ex wolfram et carbide. Est crystallus hexagonalis niger cum nitore metallico, cuius duritiem adamantino similis est. Wolframus carbide bonus est conductor electrici et caloris, in aqua dissolvere non potest, acidum hydrochloricum vel acidum sulphuricum, sed facile dissolvi in solutione mixta acidi nitrici. et acidum hydrofluoricum. Carbida pura fragilis est, sed addens titanium vel cobaltum et sinteratum, asperitas multo altior erit. Wolfram carbide etiam carbide tungsten appellatur.

Tungsten metallicum/Tungsten metallicum:Tungsten etiam wolfram vocatur, maxima forma metalli tungsten in applicatione industrialis carbide tungsten. Factory metalli tungsten Toonney virgas carbidas solidas per multos annos generavit et domi militiaeque bonam famam accipit.

Packaging Details: Saccus plasticus, deinde in spuma munitus iacebat, tandem ad lobortis exterius.

Exemplaria:Virgae carbidae solidae, quae ex communi iusto inventario nostro praesto esse possunt, pro gratis praeberi possunt. Pro solidis carbide virgae, quae speciales emptores irregulares requiruntur, onerentur. Utique clientes pro mercede navium solvere debent. Fere tempus exemplorum plumbum intra dies 7working erit.

Minimum Quantitas Ordinis: Nulla quantitas minima ordinis carbide solidorum virgarum primi iudicii ordo est. Secundo autem ordine, summa virgarum carbidum solidorum non minus quam 1000 USD esse debet.

Tempus adferendi: 7-15 operantes dies

![]() Secare Tools Grade Mensam et Applicationem

Secare Tools Grade Mensam et Applicationem

| Gradus | Co% | Frumentum (μm) | Densitas(g/cm3) | Duritia (HRA) | TRS(N/mm2) |

| TU90 | 9.0 | 0.2 | 14.35 | 94.1 | 5200 |

| TF06 | 6.0 | 0.6 | 14.81 | 93.1 | 4000 |

| TU06 | 6.0 | 0.4 | 14.8 | 94.3 | 4600 |

| TU08 | 8.0 | 0.4 | 14.52 | 93.5 | 4800 |

| TU08S | 8.0 | 0.3 | 14.5 | 93.6 | 5000 |

| TU40 | 10.0 | 0.8 | 14.4 | 91.7 | 4600 |

| TU40F | 10.0 | 0.6 | 14.45 | 92.3 | 4600 |

| TU40S | 10.0 | 0.5 | 14.5 | 92.5 | 4800 |

| TU44 | 12.0 | 0.4 | 14.1 | 92.6 | 4800 |

| TU25 | 12.0 | 0.6 | 14.06 | 92.5 | 4200 |

| TU45 | 13.0 | 0.3 | 13.95 | 92.7 | 4800 |

| TU55 | 13.0 | 0.3 | 13.92 | 92.6 | 4800 |

![]() Application commendatur

Application commendatur

| Gradus | Commendatur application |

| TU90 | Ad instrumenta machinis exstinguendam materiam (HRC65-70), durae et altae serratores poliendi. Praeclarus pro serratoribus consummare machining 316L stinless steel |

| TF06 | Aluminium magnesium stannum, graphitum et compositum fibra ad instrumenta machinandi. |

| TU06 | Enim PCB Micro-terebra et finis molendini machining eximius phaleras metalla. |

| TU08 | Ad PCB Micro-terebra, mini milling dromonem. |

| TU08S | Exercitatio micro PCB, instrumenta secanda pro materia machinis exstinctis (HRC60-65), 316L ferrum immaculatum, altum schedam metallicam expolitio et chartam siliconis ferri motoris. |

| TU40 | Commune enim terebra momordit , fine mola ac pungendo intereunt. |

| TU40F | Commune enim terebra momordit, finiunt molam machinam Titanium mixturae, ferro immaculato, et ferro cinereo fusi. |

| TU40S | 316L Pro ferro immaculato, optima materia pro communibus rotundis cuctters. |

| TU44 | Ad instrumenta machinationis admixtionis titanium secanda, calor resistens mixturae, chalybs immaculata, ferrum exstinguitur (HRC55 et supra), ferrum glaucum iacit. |

| TU25 | Ad instrumenta machinandi calor secandum ferrum tractavit (HRC45 et supra), ferrum conjecit, ferrum immaculatum. |

| TU45 | Ad instrumenta machinandi Titanium secandum, calor resistens mixturae, chalybs immaculata, ferro restincto (HRC60 et supra) |

| TU55 | Gradus cum alta duritia rubra, bonum instrumenta ad machinis secandas caliditas resistens mixturae, ferro extincto (HRC60 et supra) et stannum titanium. |

![]() Specification of solid Carbide Rods

Specification of solid Carbide Rods

| Diae. diam mm |

Tolerantia. (mm) | Longitudomm) | Tol.(mm) | Dia.Ø(mm) | Tolerantia. (mm) | Longitudomm) | Tol.(mm) |

| 2.0 | +0.30/+0.15 | 330 | 1.5 | 16.5 | +0.8/+0.3 | 330 | 1.5 |

| 2.5 | +0.30/+0.15 | 330 | 1.5 | 17.0 | +0.8/+0.3 | 330 | 1.5 |

| 3.0 | +0.50/+0.30 | 330 | 1.5 | 17.5 | +0.8/+0.3 | 330 | 1.5 |

| 3.5 | +0.50/+0.30 | 330 | 1.5 | 18.0 | +0.8/+0.3 | 330 | 1.5 |

| 4.0 | +0.50/+0.30 | 330 | 1.5 | 18.5 | +0.8/+0.3 | 330 | 1.5 |

| 4.5 | +0.50/+0.30 | 330 | 1.5 | 19.0 | +0.8/+0.3 | 330 | 1.5 |

| 5.0 | +0.50/+0.30 | 330 | 1.5 | 19.5 | +0.8/+0.3 | 330 | 1.5 |

| 5.5 | +0.50/+0.30 | 330 | 1.5 | 20.0 | +0.8/+0.3 | 330 | 1.5 |

| 6.0 | +0.50/+0.30 | 330 | 1.5 | 20.5 | +0.8/+0.3 | 330 | 1.5 |

| 6.5 | +0.50/+0.30 | 330 | 1.5 | 21.0 | +0.8/+0.3 | 330 | 1.5 |

| 7.0 | +0.50/+0.30 | 330 | 1.5 | 21.5 | +0.8/+0.3 | 330 | 1.5 |

| 7.5 | +0.50/+0.30 | 330 | 1.5 | 22.0 | +0.8/+0.3 | 330 | 1.5 |

| 8.0 | +0.50/+0.30 | 330 | 1.5 | 22.5 | +0.8/+0.3 | 330 | 1.5 |

| 8.5 | +0.50/+0.30 | 330 | 1.5 | 23.0 | +0.8/+0.3 | 330 | 1.5 |

| 9.0 | +0.60/+0.30 | 330 | 1.5 | 23.5 | +0.8/+0.3 | 330 | 1.5 |

| 9.5 | +0.60/+0.30 | 330 | 1.5 | 24.0 | +0.8/+0.3 | 330 | 1.5 |

| 10.0 | +0.60/+0.30 | 330 | 1.5 | 24.5 | +0.8/+0.3 | 330 | 1.5 |

| 10.5 | +0.60/+0.30 | 330 | 1.5 | 25.0 | +0.8/+0.3 | 330 | 1.5 |

| 11.0 | +0.60/+0.30 | 330 | 1.5 | 25.5 | +0.8/+0.3 | 330 | 1.5 |

| 11.5 | +0.60/+0.30 | 330 | 1.5 | 26.0 | +0.8/+0.3 | 330 | 1.5 |

| 12.0 | +0.60/+0.30 | 330 | 1.5 | 26.5 | +0.8/+0.3 | 330 | 1.5 |

| 12.5 | +0.60/+0.30 | 330 | 1.5 | 27.0 | +0.8/+0.3 | 330 | 1.5 |

| 13.0 | +0.60/+0.30 | 330 | 1.5 | 27.5 | +0.8/+0.3 | 330 | 1.5 |

| 13.5 | +0.60/+0.30 | 330 | 1.5 | 28.0 | +0.8/+0.3 | 330 | 1.5 |

| 14.0 | +0.70/+0.30 | 330 | 1.5 | 28.5 | +0.8/+0.3 | 330 | 1.5 |

| 14.5 | +0.70/+0.30 | 330 | 1.5 | 29.0 | +0.8/+0.3 | 330 | 1.5 |